Packaging machine for Walz-Mühle

Automation has increased productivity, optimised space and made employees’ work easier.

The Walz-Mühle mill, located in Altheim (Germany), is a historic mill producing flour, cereals, baking mixes, baking seeds and oils, as well as specially requested special mixes.

The mill has a long historical tradition of craftsmanship, describing the manual work that includes farmers, managers and operators. They themselves claim to work with their own hands as the five generations before them did.

In this view of craftsmanship, they realised that the production capacity remained the same because of the long line of preparatory operations they were required to do. In particular, compared to the rest of the German market, which had the advantage of technological help, what slowed them down was the packaging of flour, which required time and dedicated personnel.

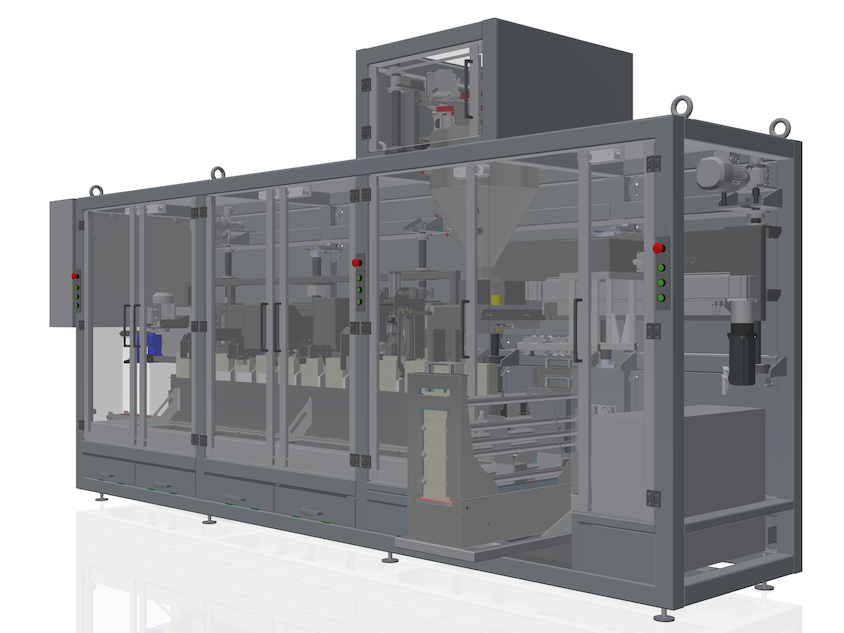

These were the reasons that drove Walz-Mühle to compromise with technology and they did so by relying on us. What we offered them was a compact and versatile preformed bag packaging machine for all kinds of products from 1.0 to 2.5 kg. The machine was created in full compliance with the customer’s requirements:

- a packaging machine suitable for different types of flour;

- a choice of different types of closure, such as double folding fin with stitching, double folding fin with hot melt;

- A change-over time of only 15 minutes to go from 1.0 kg to 2.5 kg;

- A compact machine size that allows access to the production area without any masonry work.

So, if initially they were only motivated by the need to increase production without increasing personnel, as they proceeded with the project they realised that their priority was to increase production while retaining the craftsmanship that has always distinguished them, remaining positioned in the high quality market without becoming a real factory.

Our automatic packaging machine was, for the customer, the perfect solution thanks to the rustic look of the bag and the total control that the operator has over the machine, creating a new relationship that has become increasingly consolidated over time: craftsmanship and automation.

Within just a few months, the company has repositioned itself as an industry leader, mainly due to the speed of bagging, which previously slowed down the production process and forced Walz-Mühle to look for an optimal solution.

Soon the customer will start a further project: automatic bag palletising.

Do you have any particular need or request regarding technological integration in your system?

We are glad to provide you with consultation and customized "turnkey" solutions.